In order to better serve the global market, Xinguangzheng has obtained CE certification (EN1090 certificate), ISO 9001, International Ordinary Steel Structure High-grade certificate and China Overseas Contracting Project Operation Qualification certificate. We cooperated with the countries along the "Belt and Road" and relevant enterprises, and actively explored the development of internationalization for the global market.

1

/

of

6

ShoppingTogether

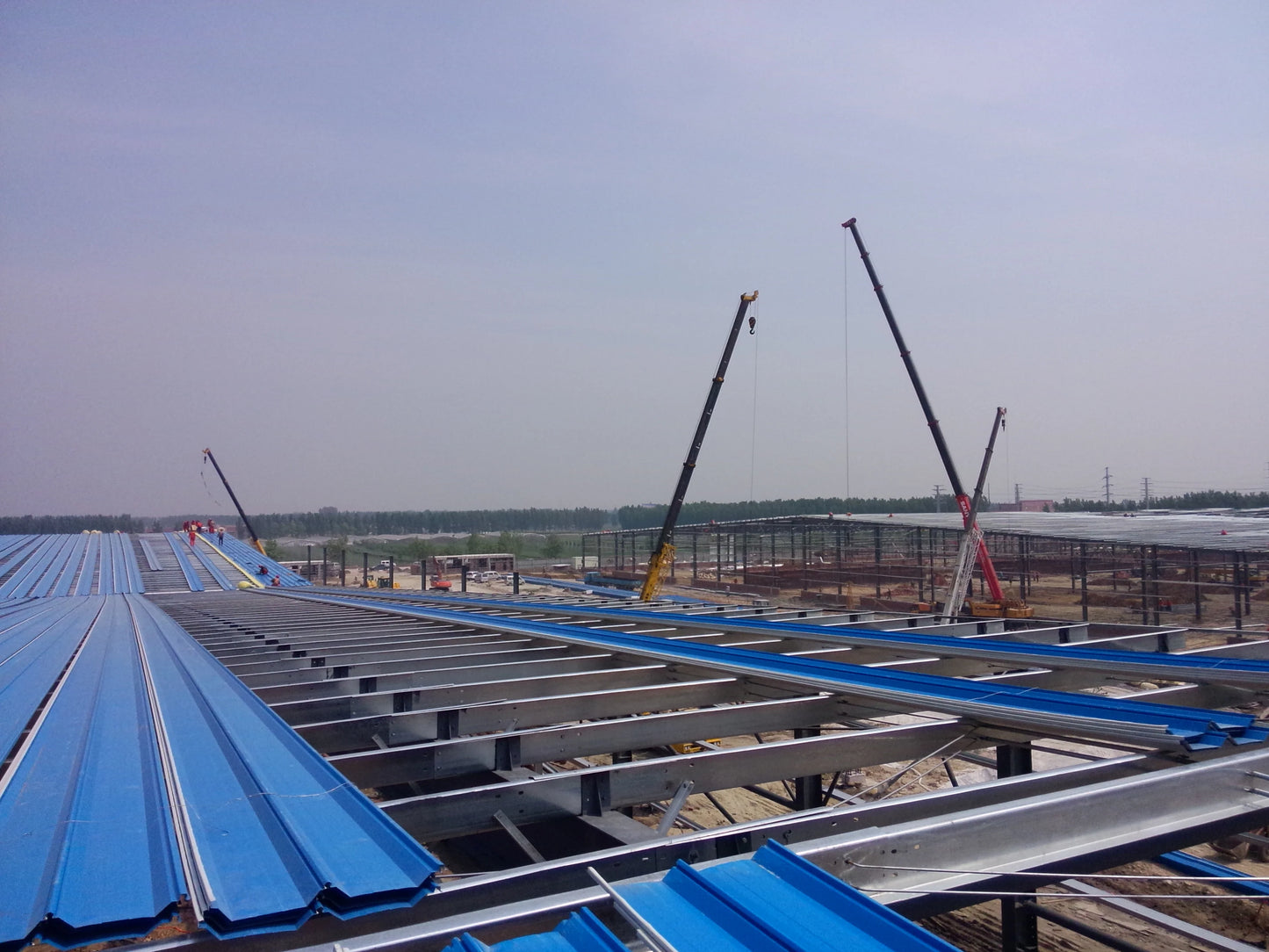

Attractive Price New Pre-engineered Steel Structure Electric Appliance Warehouse

Attractive Price New Pre-engineered Steel Structure Electric Appliance Warehouse

Regular price

₱65.00 PHP

Regular price

₱65.00 PHP

Sale price

₱65.00 PHP

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

Product Description

What is prefabricated steel structure building?

Steel structure building is built over three members connected to each other by bolts and screws: Primary members (columns, beams) Steel columns will be H section steel, square tube steel according to different type of buildings. Steel beams are usually H section steel. Secondary members (C or Z purlins, bracing...) Roof and wall sheeting or sandwich panel (EPS, fiberglass wool, PU sandwich panel) Other building components (Rolling doors, aluminium windows, etc.) The entire primary members and secondary members are designed and fully fabricated including cut-to-length, punching, drilling, welding and performing in the factory before shipping to the site for erection. At the site, all components are assembled and jointed via nut & bolt connections; thereby reducing the costs and assembly times. These buildings can be provided with different structural and non-structural additions such as ventilators, doors & windows, trusses, mezzanine floors, canopies, crane, insulation…, based on the customer's requirements.

Steel structure building material

Specification

|

Steel structure warehouse

|

||

|

Item

|

Specification

|

|

|

Steel column

|

Q235,355B welded square tube column/Box column

|

|

|

Steel beam

|

Q235,355B welded square tube column/Box column

|

|

|

Steel purlin

|

C/Z section purlin or square tube

|

|

|

Downpipe

|

UPVC

|

|

|

Gutter

|

Stainless steel gutter/UPVC gutter

|

|

|

Roof material

|

Corrugated steel sheet/sandwich panel

|

|

|

Wall material

|

Corrugated steel sheet/sandwich panel

|

|

|

Door

|

Rolling door

|

|

|

Window

|

Aluminium window

|

|

Advantages of steel structure building

1. Construction period of steel structure building is short. During the construction process, it is easy to process and fast. 2. Small lateral rigidity, lightweight, and a small amount of soil for foundation construction, little damage to the precious resource of land. 3. The building space fully utilized without waste of land area. The steel frame structure has a relatively small column cross-section. Compared with other types of buildings, it can increase the area of the building. The frame structure can provide ample internal space, make the layout of the building flexible, and is suitable for various types of utility functions. The steel structure is lightweight, excellent seismic performance, fast construction speed, and a high degree of mechanization. 4. It has excellent earthquake resistance and can weaken the earthquake response. 5. When the service life of the building expires, there is less solid garbage generated by the demolition of the structure, and the steel resources can recycle. 6. The components of the steel frame structure manufactured in the factory, the quality is easy to guarantee, and the accuracy is higher. The steel frame structure has extensive use of space and a flexible layout. It widely used in public buildings, such as the multi-story industrial workshop building, multi-story residential buildings and office buildings, and multi-story hotels. Or some hospital’s buildings, school buildings, shopping malls. The construction of the frame structure is simple, the installation is also convenient, and the materials are sturdy and durable.

Steel structure installation The prefabrication and assembly of steel components are carried out on the steel platform according to the installation sequence and process requirements, and the welding quality must be guaranteed. The distance between the splicing flange plate splicing seam and the web splicing seam of the profiled steel should be greater than 200mm. The splicing length of flange plates should not be less than 2 times the plate width; the splicing width of web plates should not be less than 300mm, and the length should not be less than 600mm. In order to facilitate the welding and ensure the welding quality, try to make butt welding on the steel platform on the ground according to the size of the construction drawing, as far as possible, the stiffener plates, connecting plates, backing plates, and beams (beams) on the columns and beams. In addition to the fabrication and assembly of prefabricated steel components on the steel platform according to the construction drawings and specifications, the manufacturability of on-site installation and changes in installation dimensions should also be considered.

Company Profile

Xinguangzheng

Qingdao Xinguang Zheng Steel Structure Co., Ltd. was established in 1997. After 25 years of steady development, it has become a high-tech, diversified, export-oriented international private enterprise integrating research and development, design, production, installation and construction and service.

Product packaging

Customer Photos

Certifications

FAQ

Q: Are you trading company or manufacturer ?

A: We have our own steel structure, steel sheet and sandwich panel manufacturing factories. Welcome to our company to see our products and discuss your project.

Q: Can you provide on-site installation service? A: We can provide Installation guide service based on customers’ request. The shop drawing, installation drawing and video will send to client to help the site erection. If need, our engineer will come to site to guide the installation.

Q. What is the delivery time?

A: It depends on the quantities of order. Generally, the delivery time will be within 25 to 60 days.

A: We have our own steel structure, steel sheet and sandwich panel manufacturing factories. Welcome to our company to see our products and discuss your project.

Q: Can you provide on-site installation service? A: We can provide Installation guide service based on customers’ request. The shop drawing, installation drawing and video will send to client to help the site erection. If need, our engineer will come to site to guide the installation.

Q. What is the delivery time?

A: It depends on the quantities of order. Generally, the delivery time will be within 25 to 60 days.

Q. How can I get a quotation for my project?

A: Pls no hesitate to send me message here or Email me. I will reply to you ASAP. Welcome to contact me for your building!

A: Pls no hesitate to send me message here or Email me. I will reply to you ASAP. Welcome to contact me for your building!

Recommend Products

Share